Get the CNC Metal Cutting Machine Solutions You Need with nexAir

Need the Right CNC Machine for Your Metal Fabrication Needs? nexAir CNC Can Help You Get It

Looking to upgrade your CNC metal cutting machine, or adding a new one to your line? If your CNC machine isn’t “cutting it” (pun intended), nexAir can help.

Here at nexAir, we know our clients’ manufacturing and fabrication needs are unique. We offer CNC metal cutting machines for any shop size and production need. So tell us what you need. Our CNC machines get fitted into facilities that serve a wide range of industries. We can help you with a new one or upgrades that will fit into your fabrication line. Or, we can just talk about CNC metal-cutting machines. So you’ll get the information you need for the system you want.

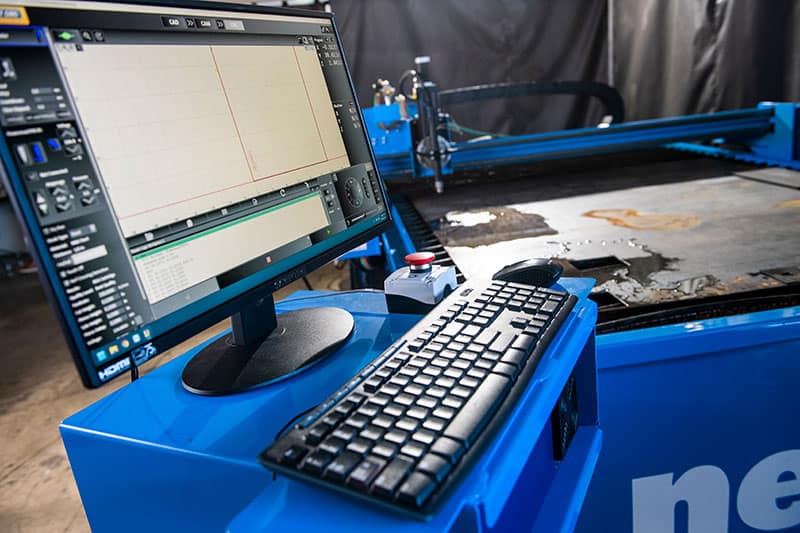

CNC Plasma Cutting Systems

Here’s What You Need To Know About CNC Metal Cutting Machines

CNC metal cutting machines are automated machines used for manufacturing parts and components. The cutting process uses software programs to cut a metal sheet into specific shapes and sizes. Hence the name, CNC, or Computer Numeric Control. Software programs are input into the machine and turned into code used to cut out the designs.

A CNC metal cutting machine offers a more dynamic way of cutting parts and components. It can cut more complex designs with a higher degree of accuracy and precision. It’s why there are countless applications for CNC machines in a wide number of industries. They are used to fabricate automotive and motorcycle parts. They are used to manufacture aerospace and defense equipment. CNC machines fabricate medical components and tools, plastic products, and more.

Explore the limitless possibilities with our team of experts.

Can CNC Metal Cutting Machines Work On Everything? A Few Advantages and Limitations

As your business grows, you’ll need to improve your production process. Getting new equipment or upgrades will help you take on more projects.

In both cases, a CNC metal cutting machine delivers speed, precision, and cost-effectiveness. You’ll need a nexAir CNC metal-cutting machine that will give you advantages like:

Cost-effectiveness

CNC metal-cutting machines are cheaper to operate than traditional fabrication machines. For lathe or milling machines, you’ll need one operator each. A well-trained CNC operator can oversee several machines at the same time. Furthermore, you save time and raw materials. CNC machines are precise and accurate. You don’t have to waste time fixing errors, and you won’t produce a lot of material waste.

Accuracy and Consistent Quality

CNC machining is more precise than manual techniques. Even better, it is repeatable without a decline in accuracy or quality. You can produce more workpieces faster and be confident that each piece is as precise as the one before.

Increased Production, Speed, and Efficiency

CNC machines use computer programs for process automation. They increase operator control and make the metal-cutting process faster and more efficient. Even pre-cutting prep is shorter and faster.

Workplace Safety

Operating a CNC machine isn’t as risky as a lathe or milling machine. Workplace accidents are reduced because CNC machines have many safety redundancies. They have machining guards, transparent doors, automatic shutoff switches, and more.

Despite its advantages, your CNC metal-cutting machine has limitations to what it can do, including:

High Initial Investment Cost

The initial cost of getting a CNC metal-cutting machine can vary depending on the type that you get. Many owners attest that a CNC machine’s consistency and quick turnaround times mitigate its cost. Its precision and high productivity rate help with return on investment. But it doesn’t detract from the fact that it is an expensive piece of equipment to invest in.

Limited Scope and Restrictions for Materials and Workpiece Size

Each CNC metal cutting machine is specific to operations and materials that it can cut. For example: if you have CNC metal-cutting machine that uses a plasma torch, you can only use it for metal fabrication. You won’t be able to redeploy it for other projects that use wood, composite materials, or plastics.

Another limitation is the output size. Most workpieces made using a CNC are limited by the machine’s size and cutting tool. Your designs can be as complex as possible but their sizes are limited to a specific range. Even if you do get or rent larger-than-average CNC machines, you’ll still be limited.

Required Training

All CNC metal cutting machines require training to use. It isn’t a plug-and-play setup and will need certification to operate. Operators will be required to train in computer-aided design. They will also be required to learn how to operate CNC machines. Many of our clients assign two-man teams to work on their CNC metal-cutting machine lines. One person is in charge of programming the designs into code. The other person is there to operate the machines. Smaller facilities often have only one person executing these tasks for one or more CNC machines.

Production Compatibility is Not Guaranteed

You may find compatibility issues with your current setup and your new CNC metal cutting machine. Or, between two different CNC models. In cases like these, you may want to call on nexAir to help you assess what needs to be done. There could be many factors that would cause these compatibility issues—or simply one.

A CNC metal cutting machine can help take your business to the next level. But it’s important to consider both the advantage and limitations of having one.

If you’re unsure of what choice is best for you, please let us know. Consulting with our nexAir experts help you as you consider all your options. nexAir CNC Plasma Cutting system, for example, is a great machine to get because it can cut metals like steel, stainless steel, and aluminum, among others, with ease. It uses a powerful plasma torch (up to 50,000 degrees Fahrenheit) for clean and precise cuts. But, its most prominent feature is also its biggest limitation: it can only work on metals. So please do let us know how we can help. Let’s assess your production requirements and how nexAir can help boost your timelines and delivery.

HIGH PERFORMANCE. SMALL FOOTPRINT

Make the most of your floor space and boost your bottom line.

LESS DOWNTIME. MORE CUTTING

Run on Day One— And Keep Running

No assembly. No hassle. No wasted time ramping up to production.

Easy to Use. Simple to Maintain

Enjoy minimal training time and set your team in motion.

The Businesses and Clients We Work With: Industries that Use CNC Metal Cutting Solutions

Here at nexAir, we work with clients and companies that serve many industries. Their equipment needs are unique as the parts and components that they fabricate for their own customers. We understand their needs and we are committed to providing them with the right CNC metal cutting machines to suit their production and assembly purposes.

Some of the clients we work with serve the following industries:

Aerospace and Aviation

The aerospace and aviation industries have extremely strict requirements. Airfoils, bushings and landing gear parts need to be precise because they endure extreme pressures and high speeds. Additionally, our clients use CNC machines to cut prototypes for testing. If it passes, the part is mass-produced. That’s another advantage of CNC metal cutting machines. The quick transition from prototype to mass production.

Military and Defense

The military and defense sector requires a lot of equipment. And parts manufacturers meet that demand using CNC metal-cutting machines. Electronic parts and transport equipment need to be precision-cut to stand up to heavy use and harsh environments. And like aviation, our clients use CNC metal cutting machines to fabricate prototypes for testing and rollout.

Transportation

In transportation, high-quality components and parts are absolutely essential. This is especially true for freight and passenger trains, buses and trucks, shipping vessels, and more. The process of creating components for the transport industry is crucial, too. And this is where machines like nexAir’s CNC Plasma Cutting system come in, for its speed, accuracy and precision.

Medical

The medical industry relies heavily on fabricators for precision equipment. Especially when much of the equipment is disposable, by mandate. Thus, the demand for high-quality parts and components is huge. Parts for electronic devices, sterile packaging, medical instruments, and implants. This presents an opportunity for many clients like you. This could be a way for you to grow your operations into industries like the medical field.

Oil and Gas

Many of our clients work in the oil and gas industry. They manufacture parts and components that are expected to be used in harsh conditions and lots of wear and tear. That’s why they rely on CNC metal-cutting machines. CNCs are used to cut components for drilling collars, valve systems, submersible systems, hydraulic and lift parts, and more.

Marine

Like oil and gas, the marine industry requires dependable components. They need to be resistant to the effects of water, extreme weather, and general wear and tear. This is why our clients use CNC metal cutting machines. They fabricate propellers, engine and electronic parts, electrical and insulation cases, and more. CNCs are also used for the fabrication of custom parts for watersports.

Is a nexAir CNC plasma cutting system right for you?

What Materials Can Be Used in CNC Machining?

In a nutshell: a lot. There’s a big caveat though. There are many types of CNC machines. Each type can cut a variety of materials. You need to know which CNC machine you need for your requirements and the materials you work on before you make your purchase. Check out the section next section. We’ve outlined the three most common CNC machines used for materials cutting.

In the case of CNC metal cutting machines, you have a lot of options. nexAir’s CNC plasma cutting systems, for example, are used to cut a wide range of metals. Some of the most commonly used metals aluminum, stainless steel, nickel, carbon steel, titanium, and metal alloys. Of these materials, aluminum 6061 and 7075 are the two grades most typically used with CNC plasma cutting systems. Both metals have great strength-to-weight ratios, durability, versatility, and corrosion resistance. Using nexAir’s CNC plasma cutting systems, you can cut these metals for auto components, aircraft parts, and more.

Plasma and Oxyfuel Cutting Versus Laser Cutting: Here’s Why Your Business and Materials Decide the CNC You Need

CNC metal-cutting machines are essential in engineering and fabrication. Within this area is a CNC technique called thermal cutting. It’s reliable for many applications. Thermal cutting comes in three types: plasma, oxyfuel, and laser cutting.

Quality and Cost

The CNC plasma cutting machine is a workhorse and cuts metals of up to two inches in thickness. Cost-wise, it will depend on size and functionality. ROI periods can range from around three to six months, depending on your rate of throughput.

Oxyfuel metal cutting is highly favored for its quickness and high throughput. But it is limited to carbon steels only. Cost-wise, oxyfuel-cutting CNC machines are the most affordable, if not the most versatile.

Laser-cutting CNCs can cut through all types of metals. However, its effectiveness is limited by material thickness (up to 1/4 inch only). Also, the CNC laser cutter is the most expensive of the three. But because of its precision, and high tolerances, it is favored in the medical industry, precision equipment and tooling, and jewelry.

Productivity, Speed and Flexibility

In terms of production, CNC plasma-cutting machines outdo both oxyfuel and laser-cutting machines. They can churn out more workpieces per hour. They can be used for a wide range of functionalities. Plus, CNC plasmas cutters are the easiest to install and train for.

Would CNC oxyfuel cutting machines measure up to plasma cutters? In terms of speed and productivity, it can handle itself very well. Combined with its low initial cost and speed, an oxyfuel cutter can give you lots of value. But in terms of cutting materials, it is sorely limited because it only works with carbon steel This is one metal-cutting CNC system that needs to stay in its lane.

CNC laser cutting machines are ideal for fine work. Its rate of production, however, is not as high as CNC plasma cutting machines. So if you’re considering it for mass manufacturing, it may not be a good idea.

Choosing your CNC metal cutting system boils down to your fabrication and production needs and timelines. That’s why here at nexAir, we help clients like you by helping you decide which system would help you achieve your production goals. Be it a plasma, oxyfuel, or laser-cutting CNC machine.

Is the Level of Skill Required To Operate CNC Cutting Machines That Important?

CNC sheet metal cutting machines require highly technical knowledge and experience. That’s why here at nexAir, we offer training and refresher courses. We offer guides to help your team get up to speed on our best CNC metal cutting machines. We also provide resources to help operators refresh their knowledge and skills on the latest equipment updates.

For general manufacturing, you’ll want CNC operators with Level 1 and 2 certifications. If your fabrication facilities are smaller, get operators with Level 2 or 3 certifications. You’ll need operators who can oversee several machines at the same time. Level 4 CNC operators are the most skilled. They have the expertise and experience in a wide range of CNC machine operations, tool technologies, and CAD programming. They represent the best in the field so having one heading your team will be great.

When You Need Next-Generation Automation Solutions, Turn To nexAir CNC Metal Cutting Systems

Here at nexAir, we offer CNC metal cutting systems that are versatile and affordable. If you’re looking for CNC plasma cutting machines that provide high-quality cutting and fast productivity, you’ve come to the right place.

We provide next-generation CNC plasma-cutting machines that are highly reliable and easy to install and use. Our machines are low maintenance. They don’t require a lot of downtime checks, so the more hours they’re running, the more productive you are. We also offer training and refresher courses that are quick but comprehensive. You don’t have to worry about getting started; you can get your team up and running as soon as possible.

Download the free whitepaper

“Easily Deployable Cutting Systems”

Maintenance Schedules for CNC Metal Cutting Machines Aren’t as Intrusive as You Think

CNC metal-cutting machines are self-contained automated systems that are well-built, durable, and reliable. They don’t require a lot of downtime checks. There is, however, an industry standard. Monthly regular systems checks and full maintenance at least once a year.

With your nexAir CNC plasma cutting system, you’ll require less maintenance and downtime. But you do have the option of following this schedule. It doesn’t matter what your average production times, materials used, or load of work are. We can help you set up this schedule to ensure the continued life and operation of your machines.

Get Custom nexAir Training and Maintenance Options for Your Team

Here at nexAir, when any of our clients ask us when’s the best time to run diagnostics we recommend following the industry standard. It’s easy to follow and to get into the habit.

But we will also consider what would best fit your needs. We have clients who do mass manufacturing on larger scales and would like to have their CNCs checked a little more regularly. For that, we schedule maintenance checks on a few CNCs at a time so that there’s no assembly downtime. For our fabrication clients, they prefer calling in for any help only when they need it.

We can help you plan out your CNC machine maintenance schedule. But you’ll be interested to know our training courses cover maintenance schedules. Your operators will have a guide to performing maintenance themselves. But if you want us onsite, please contact us and we will help you with your maintenance needs.